Wind Turbine Project

Project Description

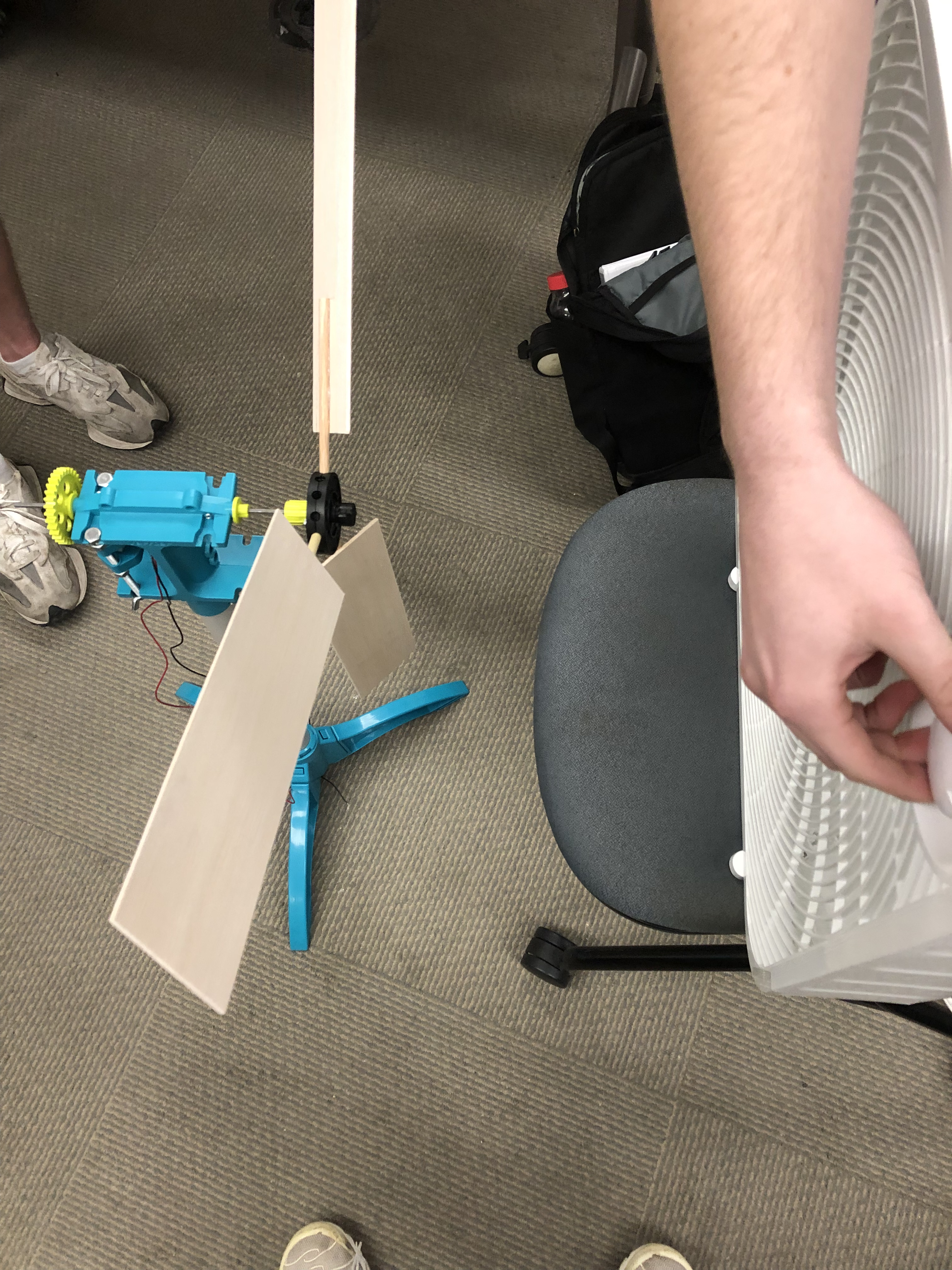

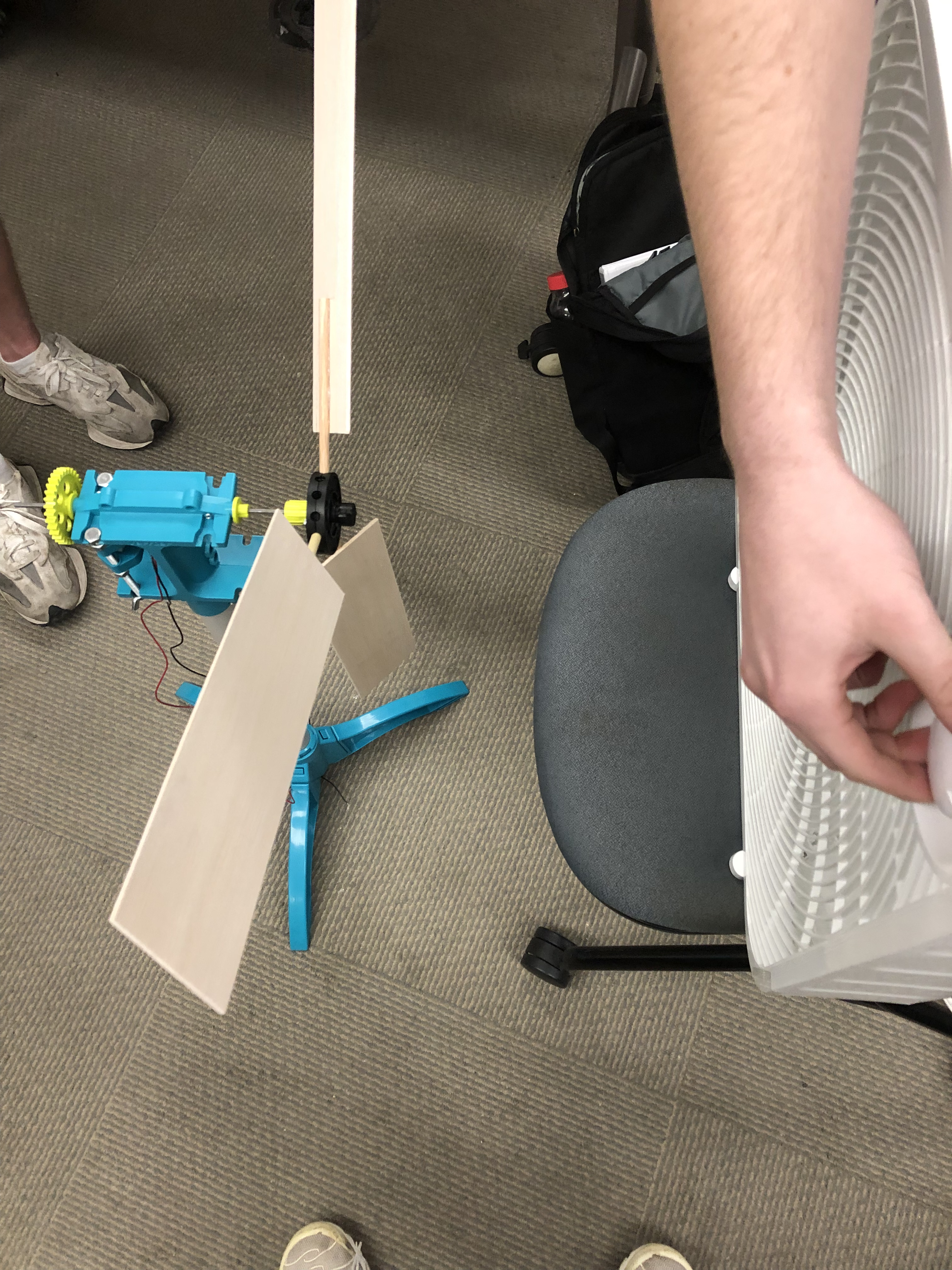

Currently, my team and I are focused on optimizing the energy conversion of a wind turbine. We're experimenting with various blade materials like wood, cardboard, and styrofoam to enhance efficiency. Using MATLAB, we are meticulously documenting the turbine's energy output to assess the effectiveness of each material and refine our design accordingly.

Blade Material

In our analysis of blade materials for wind turbines, we're considering factors such as mass, density, flexion distance, and power output for each material. In regards to these factors, we hope to identify the most effective blade material that maximizes energy conversion efficiency. This comprehensive approach allows us to make informed decisions about material selection, ensuring optimal performance and durability of the wind turbine in varying environmental conditions.

Project Conclusions

Our project concludes that a blade angle of 15 degrees is optimal, with balsa wood demonstrating the highest power output among tested materials. However, further testing may reveal an even more optimal angle or alternative blade material. This would prompt us to make adjustments to enhance turbine performance and efficiency in the future. Additionally, factors such as density and mass remain untested and could influence our findings upon examination.